What is The Crack in Coffee Roasting?

Posted by Mark Bentham, The Coffee Man on 4th Feb 2019

What Is The Crack in Coffee Roasting?

The Crack, a cool coffee roasting term, is an audible sound that is heard during the coffee roasting process.

There are 2 cracks heard during most roasting; the first and the second (makes sense huh?).

The Crack is one of 4 indicators coffee roasters use in monitoring the transition of green beans to beautiful roasted beans through the roasting process.

Why Do We Roast Coffee Beans?

Roasting dense raw green coffee beans (they are actually seeds) into beautiful brown, brittle, grindable, aromatic beans is a process that has been practised for many many years. First roasting of coffee was recorded in the 15th Century in Greater Persia and the Ottoman Empire. Development of roasting equipment and styles has changed over the years, and caters for the growing demand of around 2.25 billion cups of coffee consumed annually worldwide.

Heat evokes a chemical reaction within the coffee bean (and other foods we eat) that produces flavour and character. The heating of the food particles creates a chemical reaction between the sugars and the amino acids within the food substance. This is called The Malliard Reaction, and is responsible for the process that turns white, flavourless dough into crispy, brown, aromatic bread.

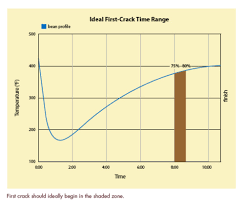

The Malliard reaction starts to kick in at about 140 – 165C, and the First Crack, which tells us the bean is on it’s way, is heard at about 196C.

Indicators of Roasting Levels

Each batch of coffee should be monitored closely to ensure it is roasting at exactly the right temperature and at the right speed in order to create the best flavour result.

Coffee roasters have the constant challenge of making sure each new roast is just perfect, and use four indicators, with sound (The Crack) being the most fun in my opinion.

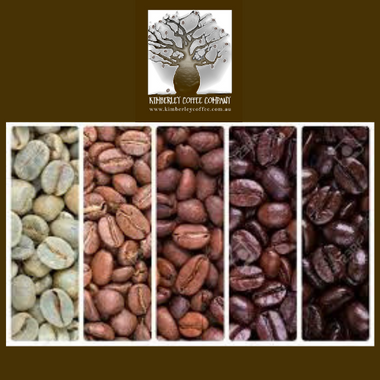

Sight – The beans change colour as they absorb heat. Moving swiftly from a pale green, to yellow, then darkening shades of brown. The browning of the bean is from the sugars inside the bean cooking. Think of the bread example again and there you have the Malliard Reaction in visible action.

Smell – As with all cooking, the aromas of the food change as they absorb heat and change form. As the beans roast, they produce the beautiful aromas and smells. A good roaster can tell exactly when the beans have reached their perfect stage.

Temperature - By using a (very special) temperature probe the roaster can gauge when the beans should be perfectly roasted because it is a chemical process and can be measured to an (near) exact outcome. Like all seeds in nature, beans from different coffee trees have slightly different physical characteristics. This, as well as time from harvest and handling, will mean the beans may react slightly differently.

Sound – The Crack is the best way to monitor the coffee beans process because it is a reaction within the bean caused by the bean hitting the different levels of ‘cooking’. The sugars are starting to It is an indicator of temperature within the bean and the changes inside the bean resulting in audible alarm bells!

The Crack Process Explained

As the little green bean is roasted it is absorbing heat. This heat absorption part is called endothermic. The bean absorbs heat until the temperature reached about 175C after which it starts to process the heat exothermically, meaning it is releasing heat, and that is when we hear the First Crack as it releases the heat (and gases) before shifting back to an endothermic process.

Over the entire process, the bean experiences weight loss of around 15-18% (yes, just in 5 minutes, wish it was as easy for humans!), and expands to almost double it’s original size due to expansion in the cellulose structure within the bean (kind of OK with this NOT being a human characteristic!).

At about 175C, just before the First Crack, the colour shifts to a lovely soft yellow and is the beginnings of a light roast. It starts to smell amazing also.

At about 196C, the first crack can be heard. It sounds like the pop of popcorn and is pretty cool to hear. You can’t miss it. Sugars are starting to release aromas, and things are rolling well for the bean! The crack comes from a combination of large amounts of water being evaporated from the beans’ structure and the expansion of steam gases inside the bean needing to be released. Crack!

At about 224C, the second crack can be heard. It is less audible than the first crack, and sounds more like the pouring of milk over rice bubbles. Not so loud, but still very much a strong indicator of the roasting process. This crack is from the internal structure of the coffee beans commencing it’s breakdown process.

What Do We Do When We Roast?

At Kimberley Coffee Company, we roast just until the second crack only and then cool the beans. The beans have just started to release some of the oils to their surface and the colour is beautiful. This makes a lovely medium roast. And explains why I can sometimes be found just standing quietly with the roaster. I am not staring into space and wondering what I will have for dinner – I’m waiting for the very important Second Crack!

If left to roast much past the second crack, the colour darkens considerably and the flavour and aromas start to be compromised. Think of overcooking that loaf of bread – it gets all hard and less yummy. Eventually, if over-roasted, the bean will fully carbonise and combust. This makes nobody happy!

Check out the colours and size of the beans as they go through the roasting process. It is truly a beautiful thing to watch beans change from little hard green seeds into the amazing happiness promoting brittle, aromatic beans of joy we use to brew great coffee.

Check out my YouTube Video all about The Crack HERE!